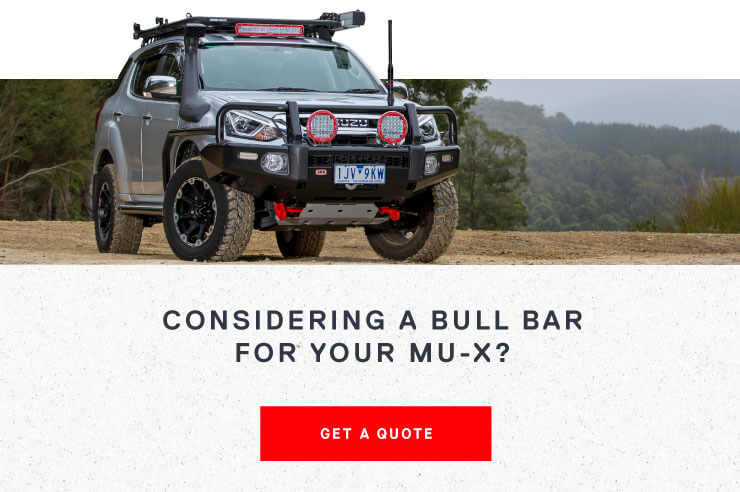

Vital for rural and remote area travel, ARB bull bars will provide substantially improved protection for vulnerable mechanical components against animal strikes whilst providing a solid base for mounting other accessories like driving lights, winches and CB antennas.

ARB bars are superbly engineered and manufactured to not only maintain maximum functionality, but also to ensure they complement the look of the vehicle.

The Summit bull bar builds on the renowned ARB Deluxe bar architecture, and integrates a fresh and contemporary design language to complement modern vehicles.

Available for MU-X models, Summit bars are winch compatible and provide next generation protection and styling for your vehicle. Laser cut holes for mounting ARB Intensity LED, IPF and Bushranger driving lights are integrated into the top pan of the bar, while ARB’s LED, indicator and clearance light assembly is included as standard.

Supplied in a durable black powdercoat finish, colour coding is available as an option for a fully integrated look.

Note: Bar shown with optional fog light kit.

Specifically designed for the Isuzu MU-X 2017 onwards model, SmartBar’s latest model of the Vehicle Frontal Protection System blends seamlessly to the contours of the vehicle, maintaining the intended aesthetics of the Isuzu design while providing unparalleled safety.

Please note: image for illustrative purposes only.

Subscribe to ARB to receive your regular 4x4 CULTURE magazine, exclusive ARB promotional news and new product release information.