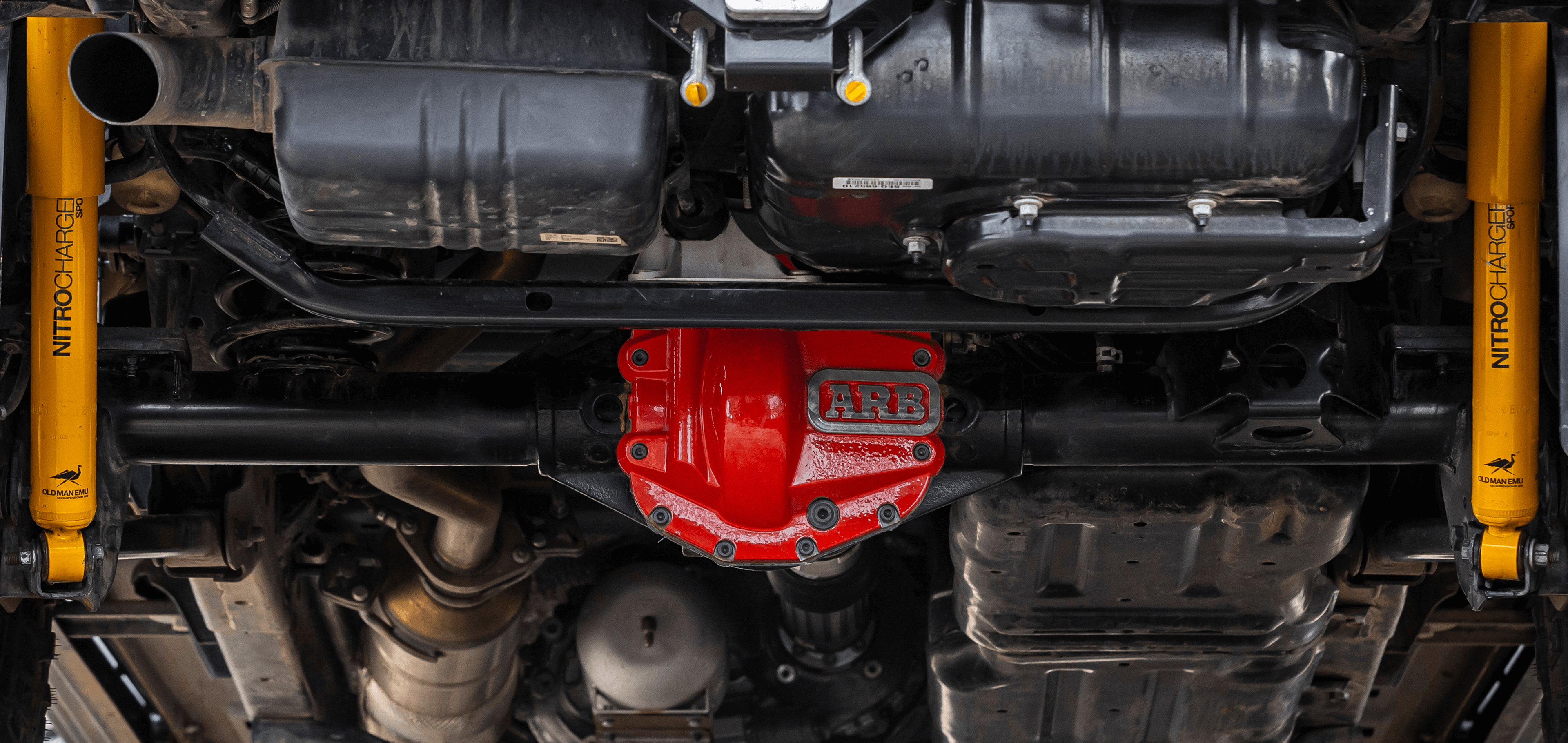

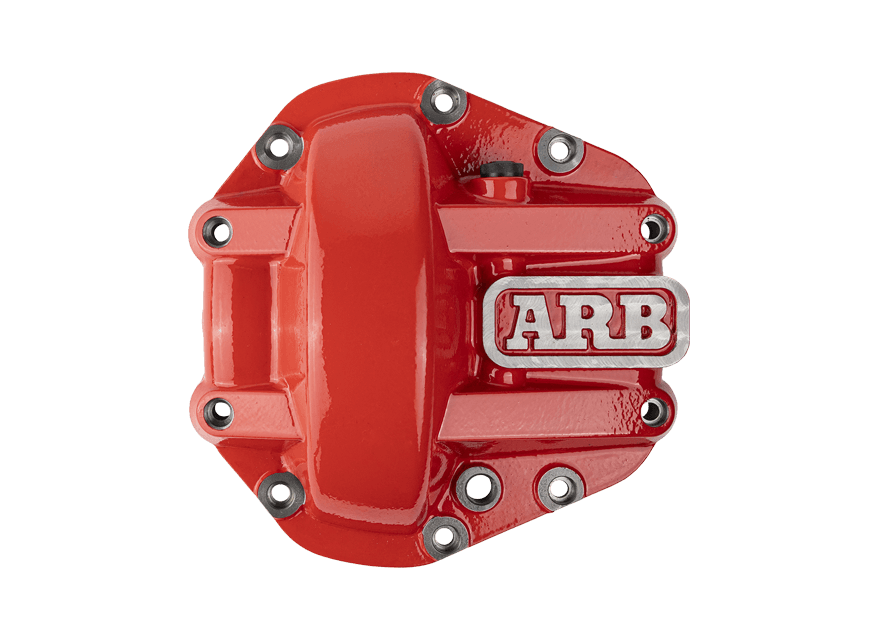

Diff Covers

When off road, it is inevitable that you’ll encounter obstacles that could potentially inflict expensive damage on your differential. ARB’s differential cover provides increased protection over factory diff covers, giving you peace of mind to tackle more challenging terrain.

Each cover is manufactured from high tensile nodule iron to protect the ring and pinion set whilst computer optimised cross bracing increases the structural integrity of the entire axle.

ARB diff covers are powder coated either red or black, CNC machined, then clear coated for a durable, professional, long lasting finish.