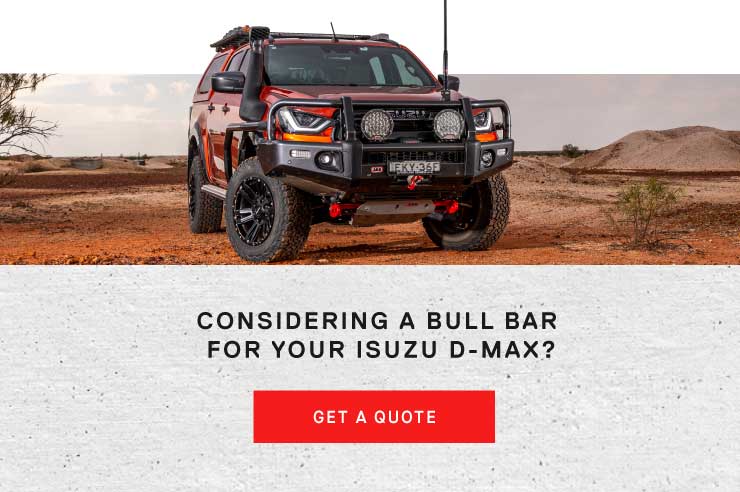

Vital for rural and remote area travel, ARB bull bars will provide substantially improved protection for vulnerable mechanical components against animal strikes whilst providing a solid base for mounting other accessories like driving lights, winches and CB antennas.

ARB bars are superbly engineered and manufactured to not only maintain maximum functionality, but also to ensure they complement the look of the vehicle.

The Summit bull bar builds on the renowned ARB Deluxe bar architecture and integrates a fresh and contemporary design language to complement modern vehicles.

Available for Isuzu D-Max 2021 4×2 High Ride and 4×4 SX, LS-M and LS-U models, as well as X-Terrain, Summit bars are winch compatible and provide next-generation protection and styling for your vehicle. Laser-cut holes for mounting ARB Intensity LED, IPF and Bushranger driving lights are integrated into the top pan of the bar, while ARB’s LED, indicator and clearance light assembly is included as standard.

Finished in a matte black powder coat, with the option to colour code to vehicle colour for a fully integrated look.

The Summit Bar to suit the X-Terrain model adds provisions for front parking sensors, OE LED fog lights and is compatible with OE flares.

Similar to the Summit bull bar, the Summit Sahara bar offers a stylish alternative that complements the vehicle design, whilst retaining many of the strength and protection features.

Offering significantly greater protection than the factory bumper, the Summit Sahara bar is available with or without the polished centre tube, and can accommodate a selection of Warn, Magnum, and Bushranger low mount winches.

Optional fog lights and colour coding can also be specified.

Incorporating many of the strength related features the Deluxe bull bar, the Commercial bar provides considerable frontal protection but achieves cost savings through a simplified manufacturing process.

ARB’s Commercial bar for the Isuzu D-Max 2021+ offers superior protection via its unique design, featuring a heavy gauge steel tube for the centre and outer frame whilst forgoing a number of cosmetic features such as colour coding and urethane buffers.

The Commercial bar is available to suit all D-Max 2021+ 4×2 High Ride and 4×4 SX, LS-M and LS-U models and is equally suited to winch and non winch applications.

Note: not compatible with the X-Terrain specification.

Specifically designed for the Isuzu D-MAX 2021, the latest model of SmartBar’s Vehicle Frontal Protection System (VFPS) complements the design and shape of the vehicle, whilst maintaining the contour lines and aesthetics. The SpartanBar functions with the Isuzu IDAS (Intelligent Driver Assist Systems) technology and maintains all of the factory accessories, whilst providing unparalleled safety.

The 2021 Isuzu D-MAX has undergone an all new exterior and chassis remodel and the team at SmartBar has developed a new frontal protection system styled to accommodate both.

Designed to suit the SX, LS-U, LS-M and X-Terrain models, the SpartanBar is engineered to be the lightest and safest VFPS available; offering even more protection and safety for D-MAX owners and now importantly, pedestrians.

SmartBar, a lighter, safer, and greener alternative to impact resistant bull and nudge bars.

Subscribe to ARB to receive your regular 4x4 CULTURE magazine, exclusive ARB promotional news and new product release information.