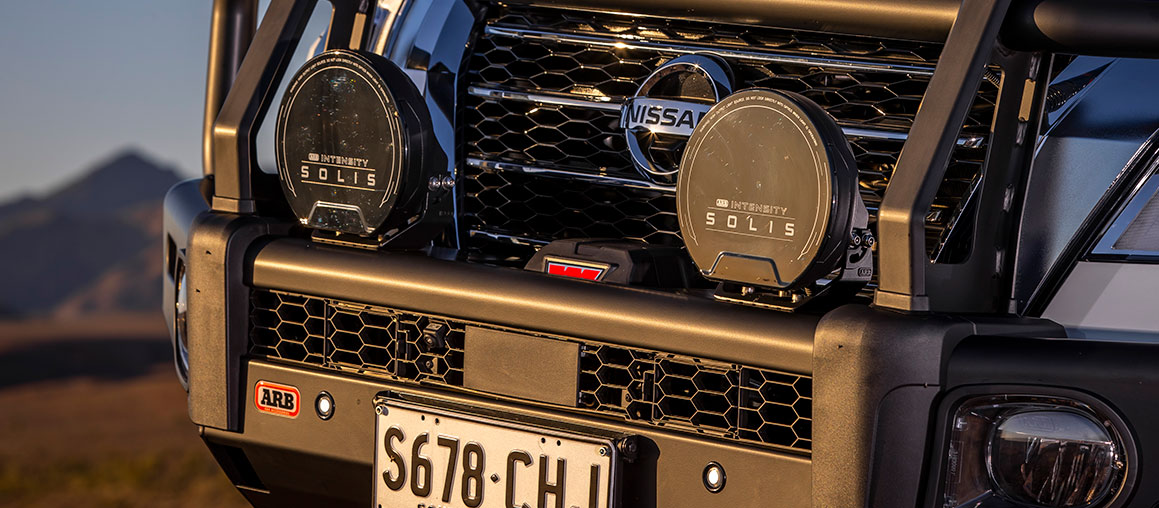

ARB Bull Bars

Vital for rural and remote area travel, ARB bull bars will provide substantially improved protection for vulnerable mechanical components against animal strikes whilst providing a solid base for mounting other accessories like driving lights, winches and CB antennas.

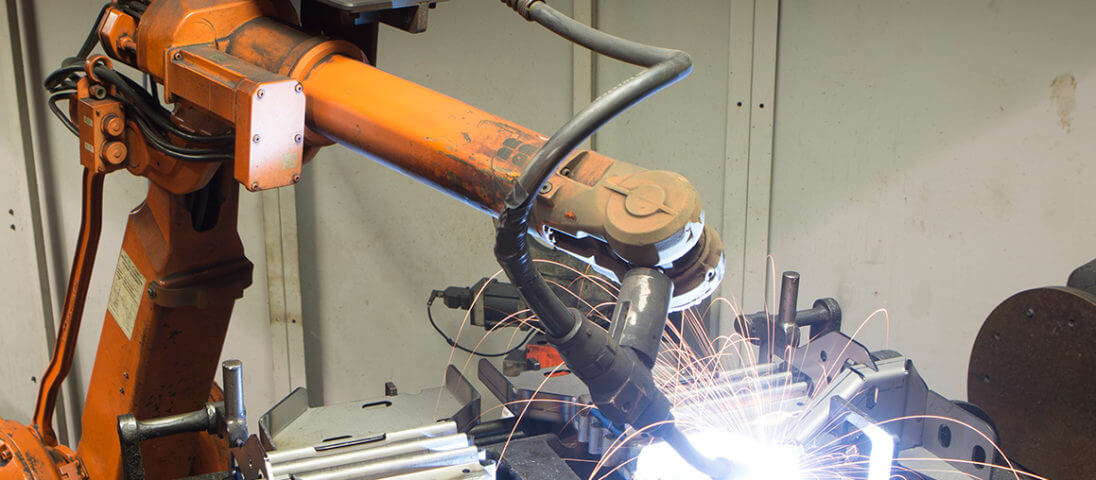

ARB bars are superbly engineered and manufactured to not only maintain maximum functionality, but also to ensure they complement the look of the vehicle.