Subscribe to ARB

Subscribe to ARB to receive your regular 4x4 CULTURE magazine, exclusive ARB promotional news and new product release information.

31st July, 2015

ARB’s Summit protection range is expanding as ARB introduces the Summit Bar for the Mitsubishi Triton MQ 2015 on models.

ARB imported an MQ Triton from Thailand to allow the extensive development work required on a brand new vehicle platform. This vehicle enabled the bar assembly to be designed and developed by ARB so it was ready for its release in Australia. Although the chassis ends are substantially different between the Thai specification and the Australian specification MQ Tritons, ARB’s engineers designed and tested bull bar chassis mounts specifically for the Australian version.

The extra design and development work of the bar allowed for an ARB recovery point and under vehicle protection (UVP) to be developed at the same time, ensuring all three components work as a protection package.

Additionally, an extended range of ARB equipment is currently being developed for the Mitsubishi MQ Triton. This range includes Summit side rails and steps, Summit rear step towbar, Commercial bar, Alloy bar and the tried and tested Classic canopy. Stay tuned for the release of these products, as well as the recovery point and UVP, shortly.

ARB Summit Bull Bar

Comprising a full range of protection systems, including front, rear and side protective options, ARB Summit was developed and styled to provide a modern interpretation of the renowned ARB protection range that would complement modern dual cab and wagon vehicles through a fresh, contemporary design language.

Building upon our proven air bag compatible bull bar mounting architecture, the Summit bull bar is the first product in the new range. Unique design elements include the 30mm edge radius on the wings and centre pan, wider press formed cover straps, 60.3mm top frame tubing, two piece polyethylene buffers and redesigned fog light surrounds, to name a few.

Provided as standard, the high output LED indicator and clearance lights provide a distinctive on road presence with long service life.

With twin aerial tabs and driving light mounting provisions, the Summit bull bar provides an ideal platform for additional vehicle accessorisation.

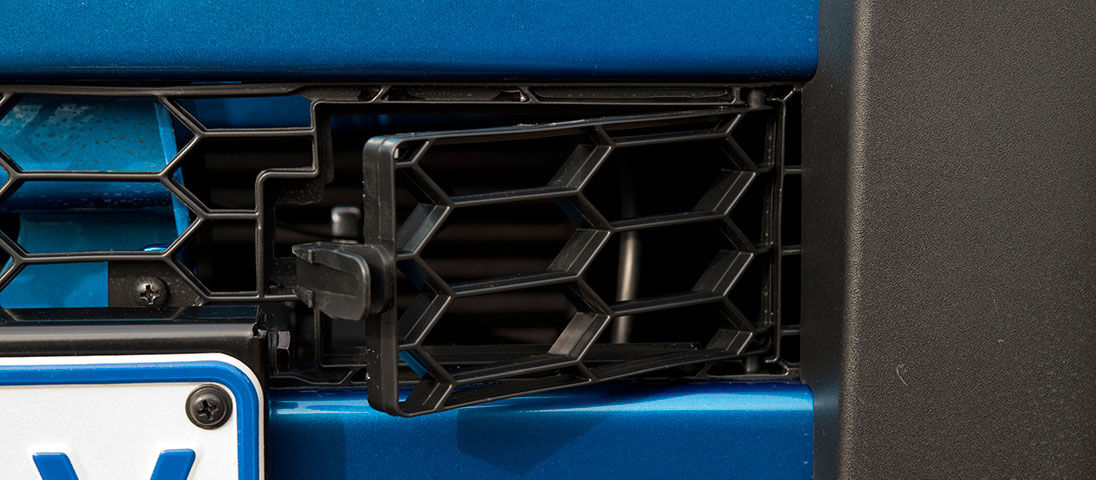

In the interest of improving usability, the Summit bull bar removes the need for winch clutch cut outs in the top pan of the bar, replaced by an easy to use access port integrated directly into the front grille section.

The Summit bar accepts a range of Warn, Magnum, Bushranger and Smittybilt winches up to 10,000lbs and is the first model to include an integrated control box mount to conceal winch electrics behind the bar. This further enhances air flow to the vehicle, while protecting the control box from damage off road.

Summit’s attention to detail continues throughout, with the inclusion of a patented side rail attachment system that couples the bull bar and larger 60.3mm side rail tubing securely without any visible fixation. A reinforced Nylon cover sleeve protects the attachment system and provides a higher level of aesthetic finish.

An all new anodised aluminium tread plate makes entering and exiting the vehicle safer and aids traction in inclement conditions.

Adding to the overall visual aesthetics of the Summit range is the use of synchro pulse controlled welding. The system controls the current pulse so only a single droplet of filler metal is detached each time, resulting in a virtually spatter free weld that offers seam quality in line with that of the TIG process.

Subscribe to ARB to receive your regular 4x4 CULTURE magazine, exclusive ARB promotional news and new product release information.